Ania Pro

฿63,450

฿40,500

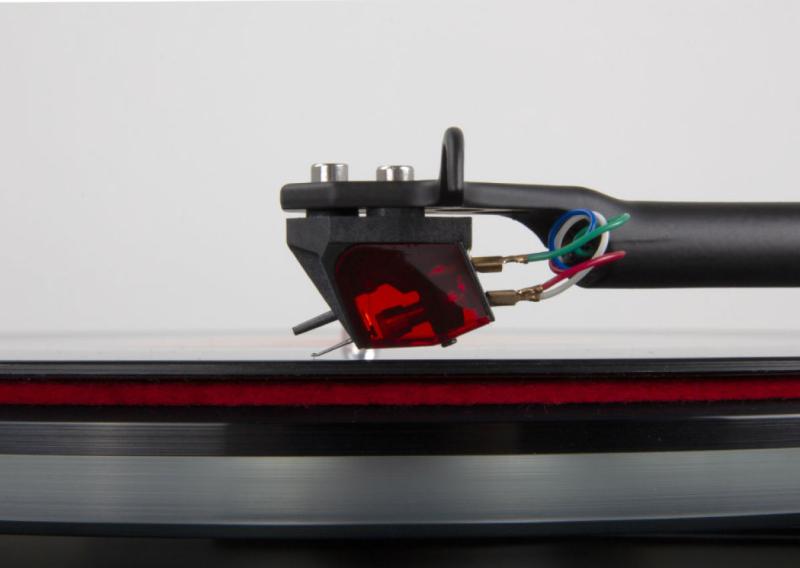

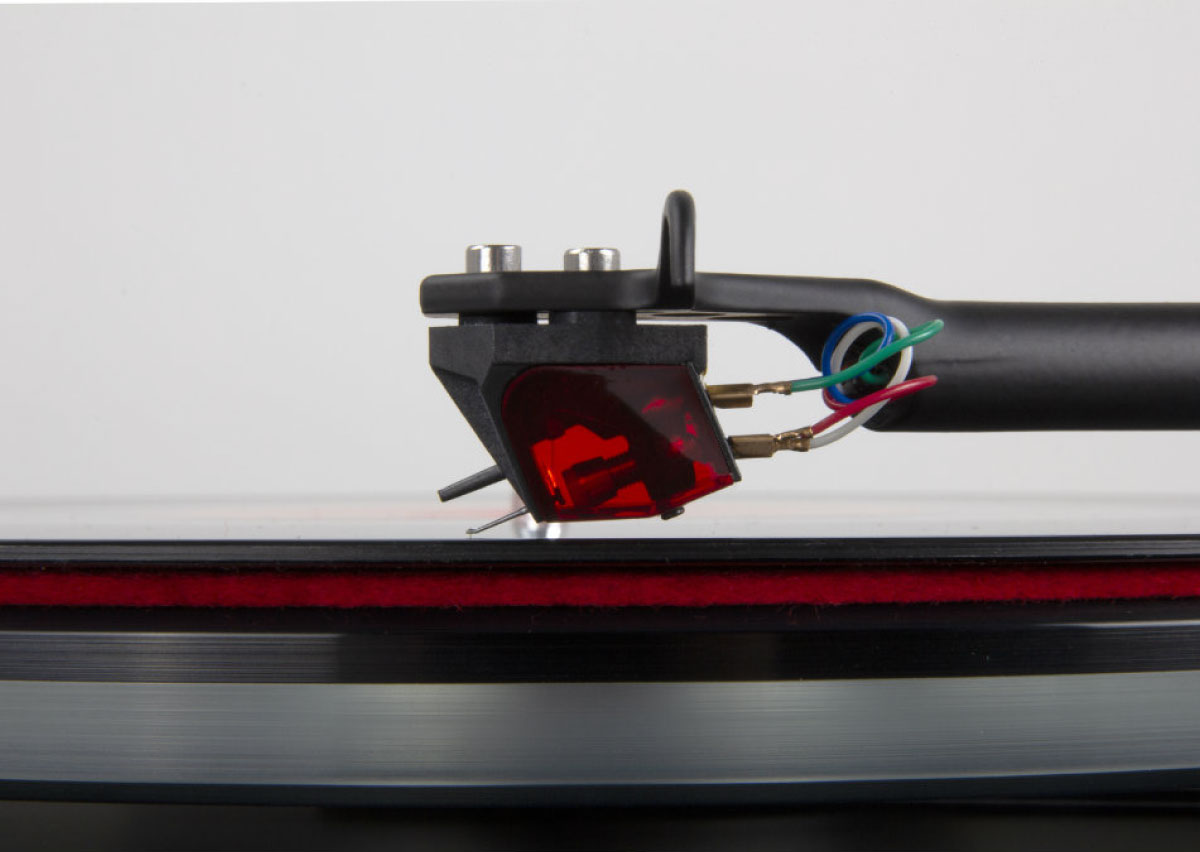

Rega’s Moving Coil cartridge design is unique in its approach to achieving an ultra-low mass generator which is undamped (no tie wire) using a unique rhomboid pivot for the cantilever powered by a purpose designed, exclusive to Rega, Neodymium magnet system.

This type of design requires a zero-tolerance engineered cartridge body which is Rega’s area of expertise and with the Apheta 3 and Aphelion products these bodies are machined from one piece of the highest quality aluminium. This is a difficult and expensive process requiring all of Rega’s forty-four years of experience to achieve. In particular, the “zero” tolerancing of the body is required in the alignment and dimension of the pivot pad mounting hole and the magnet mechanism mounting hole relationship.

The Ania Pro body uses a unique polymer/ 40% glass combination called Polyphenylene Sulphide (PPS-Fortron). The special attributes of this material are its hardness and stability in shape and dimension post moulding, both critical for the performance of Ania. Now came the challenge. Rega designed and prototyped using SLA systems in just a few months, proving the validity of the design direction.

Now we had to design a production mould tool capable of extreme accuracy and long life. PPS is a difficult polymer to mould and requires special attention to how the mould tool operates. Couple this to an almost unmouldable complex shape of the Ania body and a very considerable challenge faced the Rega engineers and the toolmakers chosen. The toolmakers are of the highest technical skill level, using the most accurate Swiss EDM CNC machines, their regular customers being the military and medical industries, routinely working down to a micron (one thousandth of a millimetre).To achieve this intricate body shape required the most complex high pressure injection mould tool that Rega has ever designed. The tool has eight major parts, four of which must move in perfect synchronicity with each other to achieve each cartridge body. The design and manufacture of this “work of art” took an entire year to produce and was made exclusively by the most senior toolmaker requiring all his lifetime of artisanal experience.

Combine this special PPS body with its high specification stainless steel inserts, a unique rhomboid pivot system, a tried and tested high performance, diamond tipped elliptical stylus cantilever with low mass moving coil generator assembly and you have new market leading musicality, performance, speed, clarity, and detail as never before at this price.

Specifications

Tracking Pressure 1.75 - 2.00g

Input load impedance 100 ohms

Output impedance 10 ohms

Nominal output voltage 350μV

Channel Balance : ≥ 20μV

Separation : ≥ -29dB

Mass 6g

Key Features :

Iron Micro cross & coil assembly

One of the world's smallest MC generators.

Cutting edge neodymium magnet.

Vital profile nude diamond stylus.

High specification fine wire.

Load settings for adjustable MC stages

Impedance -100ohm

Capacitance - 1000pF

Gain setting - High ('On' position for Rega phono stages)

Fono MC dip switches settings (factory set at Rega)

Aria MC dip switch settings for all Rega MC models

FAX : 02-721-6354

EMAIL : avstorethai@gmail.com

Power By avstorethai.com